FITINGS FORWARD FROM THE NEXT STAFF IN THE UVIA

Welded fittings are used to create fixed sealed joints. They are installed:

- in sections of the pipeline with stressful operating conditions (aggressive and abrasive environments, high pressure and temperature, vibrations, bumps) and the inadmissibility of leaks;

- in areas that do not require constant maintenance.

PRIVARY FITINGS FROM THE COMPANY ALFA-STAR

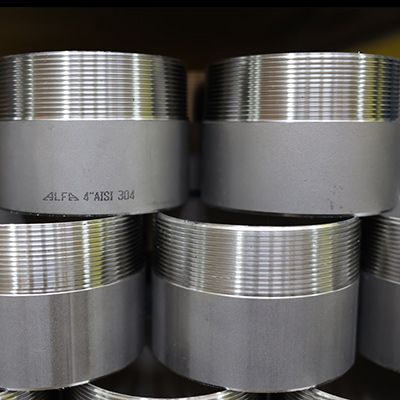

We produce and supply fittings made of AISI 304, AISI 316, AISI 321.12 (08) X18N10T, 03X17N14M2T according to DIN and GOST standards. In the assortment of the company:

- collars are stainless. Using a connecting kit, which includes a welded collar and a free flange, sections of the pipeline of different diameters are articulated and containers are connected. The resulting connection is almost sealed. Since the free flange does not have contact with the working environment, it is possible to use cheaper material (silumin) for its manufacture;

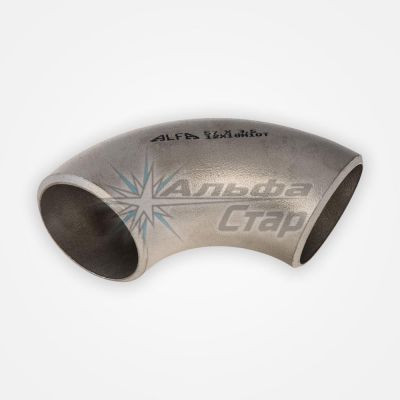

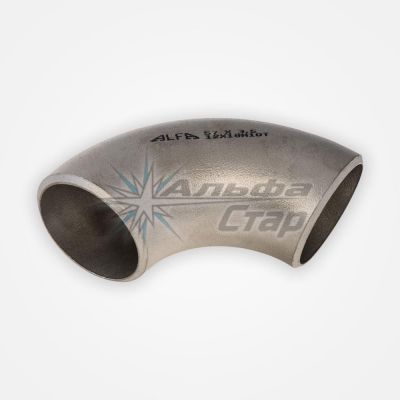

- bends to organize turns in the pipeline to a given angle, usually by 90 °. Our catalog presents 90 ° electric welded DIN and seamless GOST. The seam makes the part less durable, so electric welds are used in non-stressed sections of the pipeline;

- steel stainless transitions, creating a smooth and safe transition from one pipe diameter to another. We offer transitions DIN and GOST concentration for connecting pipes with matching axles and eccentric for articulation of areas whose axes are shifted;

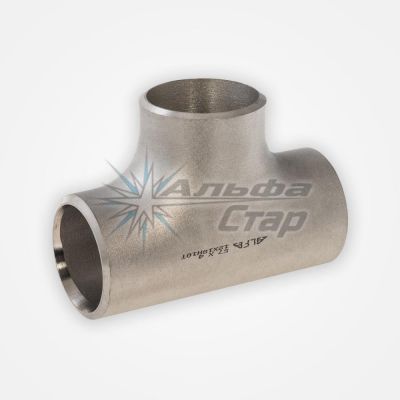

- teens in the emergency, distributing the flow of the working environment. In our catalog are electrical tealers according to the DIN standard and seamless GOST;

- stalls made of steel elliptical DIN and GOST for creating dead end branches in the pipeline. They can be used as the bottom of containers. The elliptical design creates the correct pressure distribution in the pipeline. Elliptical plugs can withstand hydraulic shock up to 16 MPa.